The company has always insisted on technological innovation drive, general manager and head of R & D ploughing industrial process furnace burner design for more than 20 years, developed a hydrogen conversion furnace low NOx burner, the use of the burner structural design, the use of flue gas FIR cycle technology, with low maintenance costs, high reliability and stability, has been widely used in the field of petrochemical hydrogen technology; developed the second generation of ultra-low NOx burner, low temperature furnace low CO / NOx dual-control type burner and so on in China’s three barrels of oil and refining applications. The second-generation ultra-low NOx burner, low-temperature furnace low CO/NOx dual-control burner, etc. have been applied in China’s three barrels of oil and the local refineries with remarkable results; participated in the development and design of the burner, which is the key equipment of the first zero-emission new process for heating furnaces in Jingbo Petrochemical Company and Sinopec Luoyang Engineering Company, and was driven to success in a single run.

At the same time of developing new technologies, we actively research and develop AR operation and digital combustion technology to achieve intelligent operation of burners and remote after-sales service, and accelerate the process of petrochemical heating furnace intelligence and digitalisation.

In order to provide customers with combustion control solutions and related products in line with their actual needs, the company has prepared for the planning and construction of the heating furnace burner test centre, which is expected to be completed by 31 December 2024, and the test centre, when completed, will play a positive role in promoting environmental protection, industrial upgrading, energy saving and emission reduction.

To provide better products and solutions, the company has planned to invest in 3D printers.

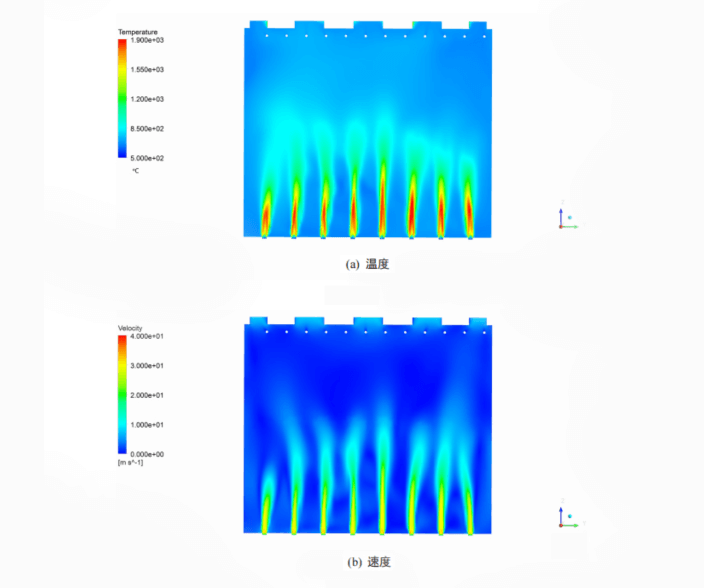

According to the actual working conditions, we can simulate and analyse the distribution of combustion field, flow field, temperature field and NOx emission in the tube under different working conditions.

This figure shows the distribution of temperature and velocity in the furnace chamber and tube simulated according to the design value of our company.